Description

Autogenous shrinkage is a crucial factor in the world of concrete construction and is a phenomenon that can significantly affect the long-term durability and performance of structures. This article delves into what autogenous shrinkage is, its causes, and how to control it effectively to ensure the structural integrity of concrete projects.

What Is Autogenous Shrinkage?

Autogenous shrinkage, also known as self-desiccation, is the volume reduction that occurs in concrete without the influence of external factors, such as temperature or moisture loss. It is an inherent property of concrete and is primarily attributed to the chemical reactions that take place within the material during the early stages of hydration. Autogenous shrinkage begins as soon as water is added to the cement, and it continues for an extended period, often several months or even years, depending on the specific concrete mixture and environmental conditions.

Causes of Autogenous Shrinkage

Several factors contribute to the development of autogenous shrinkage in concrete:

- Chemical Reactions: The primary driver of autogenous shrinkage is the chemical reactions within the concrete matrix. As cement particles hydrate and form calcium silicate hydrates (C-S-H), the structure becomes denser, leading to a reduction in volume.

- Water Content: The water-cement ratio plays a crucial role. Higher water-cement ratios can lead to more autogenous shrinkage, as excess water contributes to the formation of additional hydration products.

- Cement Type: The type and composition of cement used in a concrete mix affect autogenous shrinkage. Different types of cement have varying rates of hydration, which in turn influence shrinkage.

- Aggregate Properties: The size, shape, and surface characteristics of aggregates also influence autogenous shrinkage. Aggregates can either mitigate or exacerbate the issue.

- Admixtures: Certain chemical admixtures can be added to concrete to mitigate autogenous shrinkage by controlling the rate of hydration or by reducing water demand.

Effects of Autogenous Shrinkage

Uncontrolled autogenous shrinkage can have several detrimental effects on concrete structures:

- Cracking: The most apparent consequence of autogenous shrinkage is the development of cracks in the concrete. These cracks can compromise the structural integrity and aesthetics of the construction.

- Permeability: Autogenous shrinkage can lead to increased porosity, making the concrete more permeable. This can result in greater vulnerability to external factors such as water penetration and chemical ingress.

- Reduced Durability: Cracking and increased permeability contribute to reduced durability, shortening the service life of the concrete structure.

Controlling Autogenous Shrinkage

To optimize the durability and performance of concrete structures, it is essential to control autogenous shrinkage effectively. Here are some strategies for managing and mitigating this phenomenon:

- Proper Mix Design: Select an appropriate mix design that takes into account the water-cement ratio, type of cement, and aggregate properties. An optimized mix design can significantly reduce autogenous shrinkage.

- Supplementary Cementitious Materials (SCMs): Incorporating SCMs like fly ash or slag into the concrete mixture can slow down the rate of hydration, reducing autogenous shrinkage.

- Chemical Admixtures: Certain chemical admixtures, such as shrinkage-reducing agents, are available to help control autogenous shrinkage. These admixtures can reduce water demand and minimize shrinkage cracking.

- Curing Practices: Proper curing, especially in the early stages of concrete placement, can help control autogenous shrinkage. Moist curing or using curing compounds can mitigate the effects.

- Aggregate Selection: Careful consideration of the type and properties of aggregates can have a significant impact on autogenous shrinkage. High-quality, well-graded aggregates can help reduce shrinkage.

- Reduced Water Content: Reducing the water content in the mix while maintaining workability is a crucial aspect of controlling autogenous shrinkage. This can be achieved through thorough mix design and proper compaction.

In Conclusion

Autogenous shrinkage is a critical consideration in concrete construction. Understanding its causes and employing effective control measures can ensure the longevity, durability, and structural integrity of concrete structures. By optimizing the mix design, selecting appropriate materials, and implementing proper curing and admixtures, construction professionals can minimize the impact of autogenous shrinkage and ensure the success of their projects.

FAQs

- What causes autogenous shrinkage in concrete?

- Autogenous shrinkage is primarily caused by the chemical reactions in cement that consume water and produce hydrates, leading to a decrease in the pore solution volume within the concrete.

- How is autogenous shrinkage different from drying shrinkage?

- Autogenous shrinkage is independent of external factors like temperature and humidity, whereas drying shrinkage is caused by moisture loss due to environmental conditions.

- Why is autogenous shrinkage important in concrete construction?

- Understanding autogenous shrinkage is crucial because it can lead to cracking in concrete structures, affecting their durability and performance.

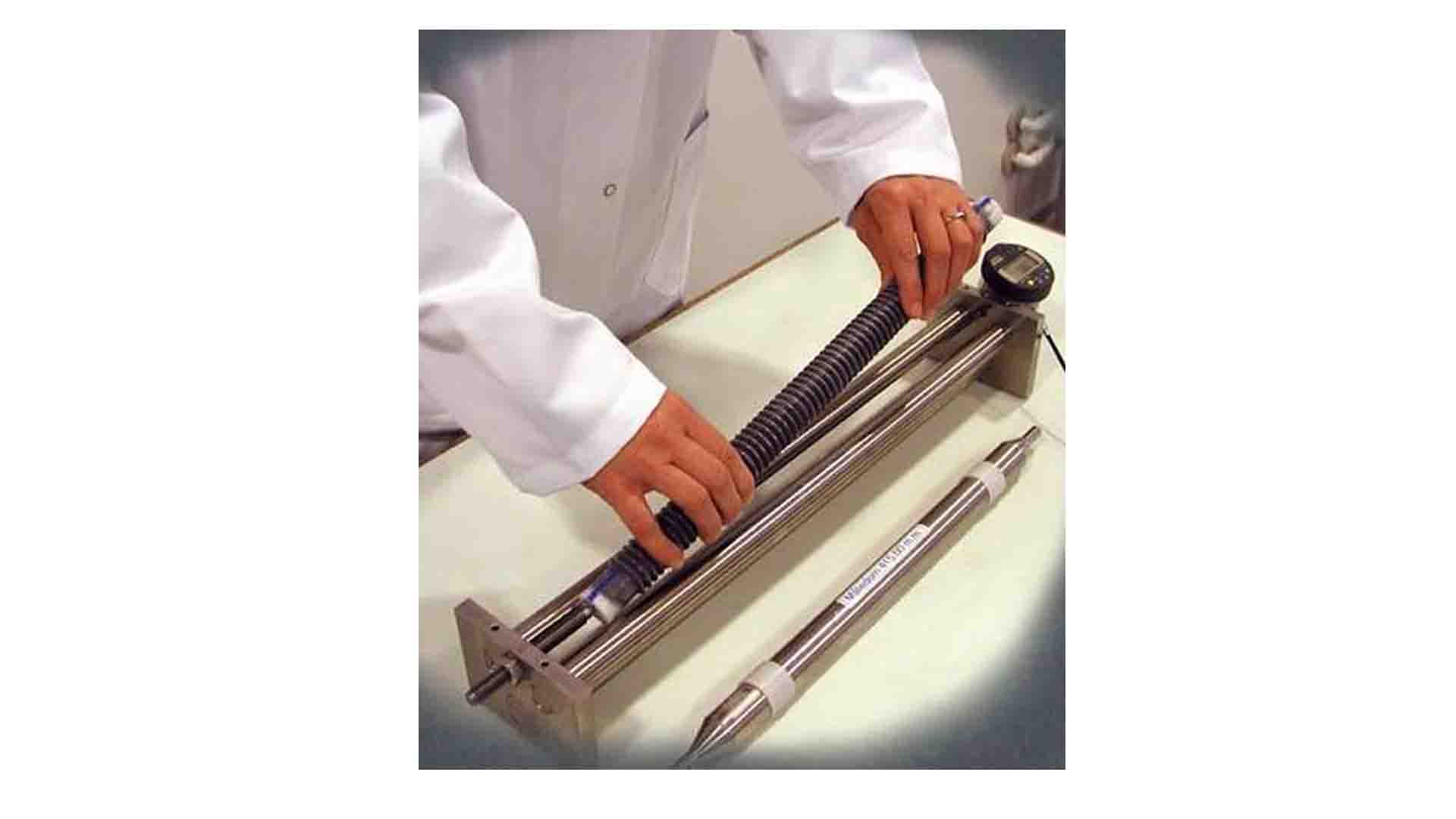

- What are the common methods for measuring autogenous shrinkage?

- The most common methods include strain gauge measurements, internal curing, and using specialized testing equipment.

- How can autogenous shrinkage be mitigated or controlled in concrete mix designs?

- Additives like shrinkage-reducing admixtures (SRAs) and supplementary cementitious materials (SCMs) can be used to mitigate autogenous shrinkage.

- Are there industry standards or guidelines for addressing autogenous shrinkage in concrete construction?

- Yes, several standards and guidelines, such as ASTM C1698, provide methods for testing and controlling autogenous shrinkage.

- What are the potential consequences of ignoring autogenous shrinkage in concrete design and construction?

- Ignoring autogenous shrinkage can result in increased cracking, reduced durability, and structural issues in concrete structures.

- How does autogenous shrinkage affect the service life of concrete structures?

- It can reduce the service life by contributing to premature cracking and compromising the structure’s long-term performance.

- Are there sustainable or innovative approaches to managing autogenous shrinkage in concrete?

- Innovative methods, such as internal curing and advanced mix designs, are being developed to reduce autogenous shrinkage while maintaining concrete strength and durability.

- What research trends are emerging in the field of autogenous shrinkage and concrete technology?

- Research is focusing on the development of new materials and technologies to better control and predict autogenous shrinkage, as well as the environmental impact of concrete production.

Reviews

There are no reviews yet.