Description

Principle

If a test specimen is subjected to mechanical impact, such as being struck by a hammer, it will vibrate at it natural or resonant frequency. The DK-5000 uses a small hammer to impact the test specimen and a small accelerometer to monitor the vibration of the specimen. By using the correct specimen support condition, the proper position of the impact point, and the correct location of the accelerometer, the resonant frequencies for different modes of vibration can be determined. The illustration below shows the locations of the specimen support(s), the impact point, and accelerometer position to measure the longitudinal, flexural, and torsional resonant frequencies. In the impact resonance method, the resonant frequency is determined by transforming the time history of the accelerometer signal into the frequency domain. The resultant amplitude spectrum will contain one or more peaks that correspond to the excited frequencies.

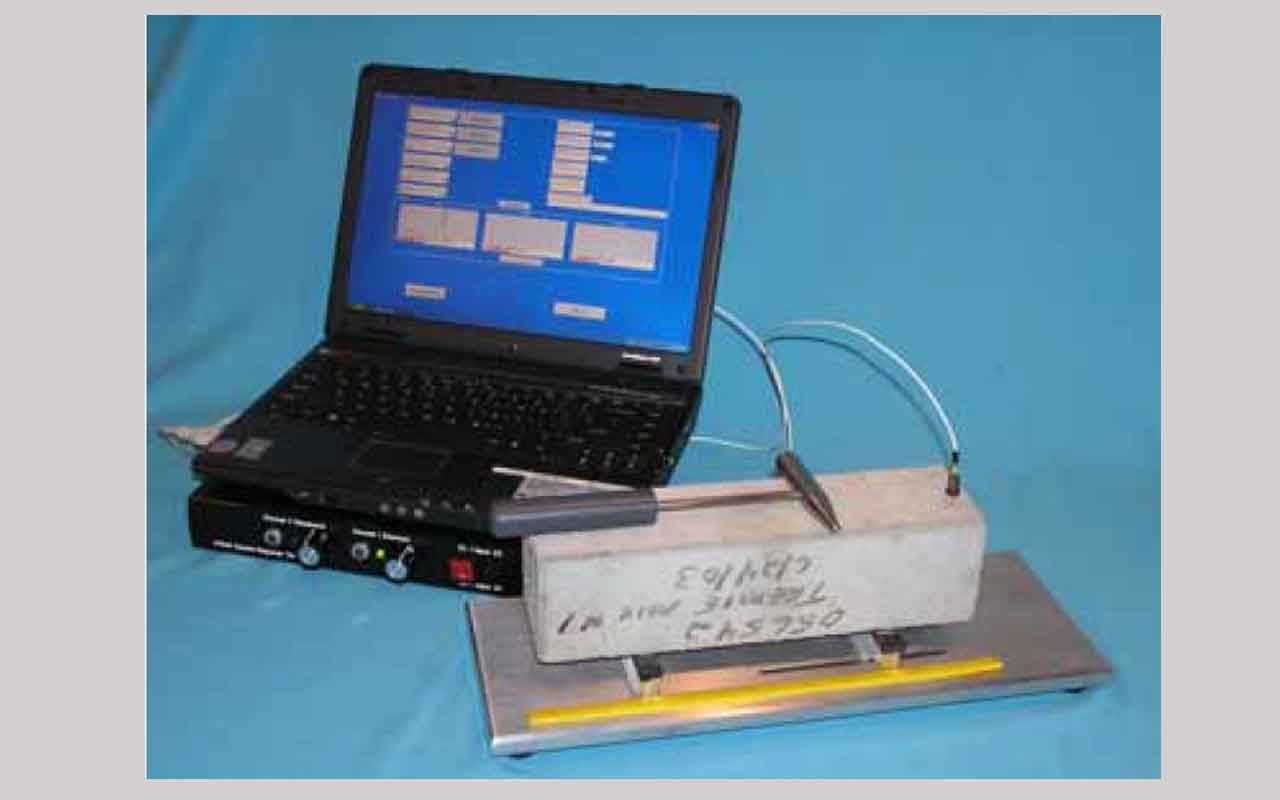

The DK-5000 consists of a laptop computer, a data acquisition and signal conditioning system, the DK Tester software, a hammer, and an accelerometer. In addition, a test bench is provided for supporting the test specimen. The DK Tester software is used to set up the testing parameters, to input specimen size and mass, and display test results. In accordance with ASTM C215, the test is repeated three times on the same specimen. The software displays each test result, and calculates the average resonant frequency.

From the specimen mass, specimen geometry, and measured frequencies, equations given in ASTM C215 are used to compute the dynamic elastic properties.

Reviews

There are no reviews yet.