It is an essential question as to which of the best ways to judge the quality of a pavement? The answer is Rolling Thin Film Oven (RTFO), which many experts recommend because its function has become luminous. You should note that the properties of the binder in Hot Mix Asphalt or HMA change regularly. These go through significant aging during handling, mixing, and baking, so you need to ensure that the final product meets the design requirements correctly. A properly designed, built, and installed asphalt pavement will have to endure many years like heavy traffic, weather conditions, etc.

What is the benefit of Asphalt pavement on the Road?

Asphalt roads or pavement offer different benefits, like cost efficiency, reduced noise pollution, and comfort for all environments. So if you use asphalt materials for constructing the Road or pavement can be advantageous for all users and the environment, as it is extremely environmentally friendly. Asphalt pavement, also known as green pavement, is completly reusable and recyclable. So you can use it again and again.

- Recycling is the main attraction of Asphalt, so the price of this product has started to increase over time. Like concrete, you can use Asphalt again to create new roads. It is much quieter than concrete. Although it makes a smooth drive on the Road, its skid resistance is higher than concrete Road for better traction.

- Asphalt roads are much less expensive than concrete roads and do not require much larger machinery. Asphalt is a quick and inexpensive solution you should use in short-term projects,

- Asphalt can absorb heat very well. Also, users often utilize the heat of the sun to clean the Road after any disaster like a storm. Besides this, Asphalt can melt the snow very quickly.

- According to the expert is perfect for rural roads as it needs less maintenance and repair.

What is the importance of RTFO testing?

Rolling Thin Film Oven (RTFO) is such a type of test that helps to measure the effect of heat and wind on a moving film utilized in the hot mix asphalt binder. The results of heat and wind during production and ripening mimic short-term aging.

This test can determine how effective the Asphalt mixture is for any construction. Therefore, before contracting Asphalt road, experts recommend using this testing equipment. To assess its performance, you can use the automatic direct shear test.

Rolling Thin Film Oven Test Method

heat and air are the essential elements of asphalt binder that need to be measured while Asphalt. So Rolling Thin Film Oven (RTFO) is vital before contracting a pavement. It can measure the heat and air’s effect on a moving film used in any hot mix asphalt binder. It can simulate the short-term aging that takes place during paving operations. This test is crucial because it helps you investigate then predict HMA pavement behavior, longevity, and distress. So the engineer needs to do this test before constructing any pavement. So it is also essential to choose the high-quality RTFOT rolling thin film oven test equipment. Without quality tools and equipment proper tests cannot be done.

RTFO Test Procedure

1. First, you need to take a specially shaped glass bottle, then take some sample of asphalt binder, heat it, and fill the sample in that special glass bottle.

2. You will then need to mount those bottles horizontally in a carousel in the oven to test them properly.

3. The next step is to heat the bottles for about 85 minutes at 15rpm heat because a jet of 325 ° Fahrenheit heated air needs to be directed between them.

4. The next step in the calculation is the final step. After completing this RTFO test, you will measure the dawn’s changes, viscosity, and other rheological features, which will significantly help you.

5. In the last step, the measurements are compared with the quality of the sample without heating

A full description of the method will help you measure the effect of heat and wind on the running film of Asphalt, so the test needs to be accurate. That is why it is crucial to hire high-quality rolling thin film oven testing tools.

The Benefits:

RTFO has many advantages that standard thin-film ovens cannot usually deliver, so the test is inaccurate.

· The carousel used in RTFO expresses heat and airflow measurements through a continuous, consistent rotating action.

· This test helps the asphalt binder modifier dispersed

· This test helps remove the surface skin, so the aging of asphalt binder can be inhibited.

· This test takes only 85 minutes to complete, so you should expedite the test time.

· Since this test is essential, you should improve the accuracy and repeatability of the test

Offer easy operation, which requires minimum training required.

What the high-quality RTFOT rolling thin film oven test equipment Cooking Up

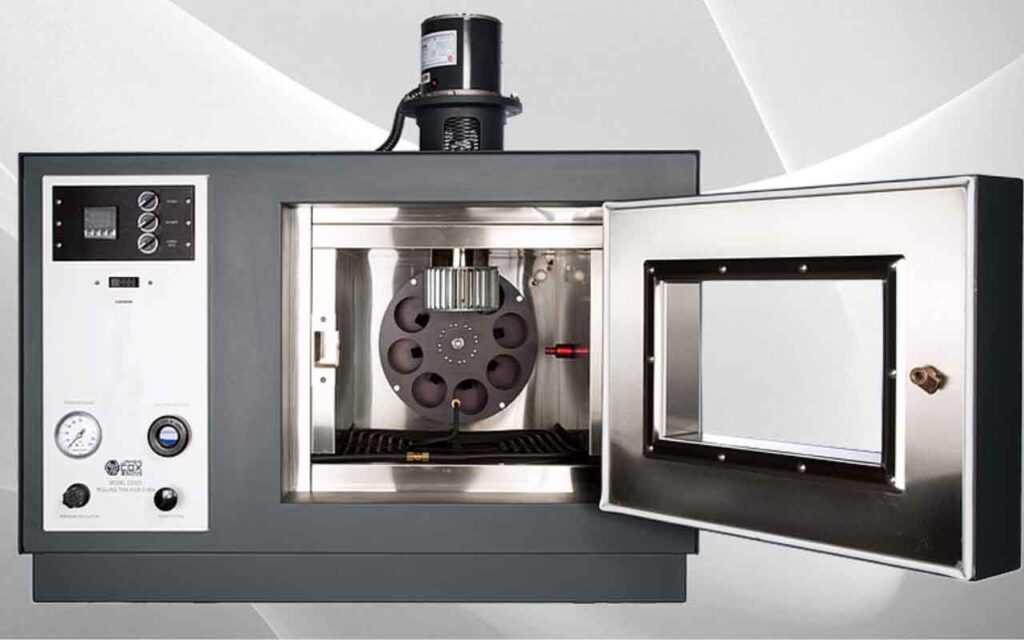

Suppose you choose high quality and updated rolling thin film oven. In that case, it is one of the modern rolling thin film oven testing machines that always comes with advanced design and durable construction. These shots give reliable and accurate results for quickly measuring the effects of heat and wind in an asphalt binder.

Precise, repeatable results and straightforward operation require precise material, as it controls the whole subject. This diagram has a built-in timer that controls test time. It performs the diagram at a temperature of 246 ° C (475 ° F), which promotes uniformity and repeatability of the test, which is also essential.

A uniquely designed carousel, a rolling thin film oven testing tool, can be loaded quickly and easily. So you need to remove scratches and damaged bottles. While exceeding recovery time requirements, laborious and accurate RTFO meets all test procedure specifications. So it is essential to use high-quality RTFOT rolling thin film oven test equipment.