Description

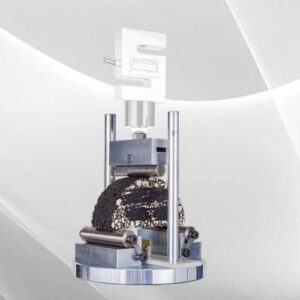

Once the test is initiated, the furnace door remains locked until test completion ensuring operator safety and test integrity during critical burn-off steps. During operations, volatiles are further oxidized in a high-temperature afterburner using a patented ceramic filter, which is heated to 650°C (1,202°F), reducing overall emissions by 95%. The NCAT Furnace can also be operated in manual mode. In this mode the furnace will beep when the endpoint is detected, however it will continue the test sequence until the operator presses “stop” to unlock the door and print the results.

The ignition furnace automatically compensates for weight change due to temperature changes and correction factors can be entered to accommodate unique mix characteristics. Endpoint detection of the test cycle can be user-programmed for a weight loss between 0.01% and 0.5% for three consecutive readings. Test results are computed as asphalt content per total weight of sample, or bitumen ratio per weight of dry aggregate to an accuracy of ±0.11%. A 24 hour/7 day timing function can be programmed to preheat the furnace at any time of day. The modular, refractory embedded heating elements have an extended service life and are easy to replace. An RS-232 port provides data interface with a personal computer for graphical data analysis.

Temperature range of the ignition furnace is: 392 to 1202°F (200 to 650°C) and provides 4,800 watt operation. An accurate internal balance monitors weights automatically throughout ignition to within ±0.1 gram. The ignition furnace comes complete with accessory package AY1087X1. This package includes: 4 baskets, 2 trays, 2 covers, handle, cooling cage, insulated plate, gloves, face shield, 4 rolls of printer tape, balance calibration plate and anderol oil. CE-approved. Chamber dimensions: 14″W x 10.5″H x 14″D (355 x 266 x 355mm). Shipping dimensions: 32″W x 32″D x 60″H (813 x 813 x 1524mm). NCAT Furnaces are not supplied with power cords and must be hard-wired directly to a suitable electrical supply or supplied with a cord and plug by the user.

Reviews

There are no reviews yet.