Description

Principle

In the Bond Pull Off Test, a disc is bonded to a prepared testing surface and the disc is pulled off after a partial core has been cut around the disc (extreme left in following figure). The pull-off force, F, is divided by the cross-sectional area of the partial core to obtain the pull-off strength fp:

where d is the diameter of the partial core.

The types of failures that can occur in a BOND-TEST are illustrated above: (a) failure in the substrate indicates that the bond strength is greater than the tensile strength of the substrate; (b) failure at the interface provides a measure of the tensile bond strength between the overlay and the substrate; and (c) failure in the overlay indicates that the bond strength is greater than the tensile strength of the overlay. During a test, it is very important that negligible bending is introduced to the disc by the loading system. Otherwise, low and erratic test results will be obtained.

Failure type (a) is preferred because it shows that the bond strength of the overlay is greater than the tensile strength of the substrate. Note that failure occurs at the weakest link of the composite system, and one cannot predict which type of failure will occur. Only tests results with the same type of failure should be averaged in calculating the average pull-off strength.

The nature of the BOND-TEST has been investigated by finite element analyses (see Petersen, C.G., Dahlblom, O. and Worters, P., “Bond-Test of Concrete and Overlays,” Proceedings, International Conference on NDT in Civil Engineering, University of Liverpool, U.K., 1997; Bungey, J.H. and Madandoust, R., Factors influencing pull-off tests on concrete,” Mag. of Concr. Res., 1992, 44, No. 158) ). Failure in the BOND-TEST using a 75-mm disc was predicted to occur at a displacement of 0.02 mm to 0.03 mm and the nominal stress in the partial core before rupture is about 3 % lower than the uniaxial tensile strength of the substrate concrete.

Variability

For 75-mm discs, the coefficient of variation of replicate test results is about 8 to 10 % on concrete with a maximum aggregate size of 38 mm. For 50-mm discs, the coefficient of variation is 14 to 16 %.

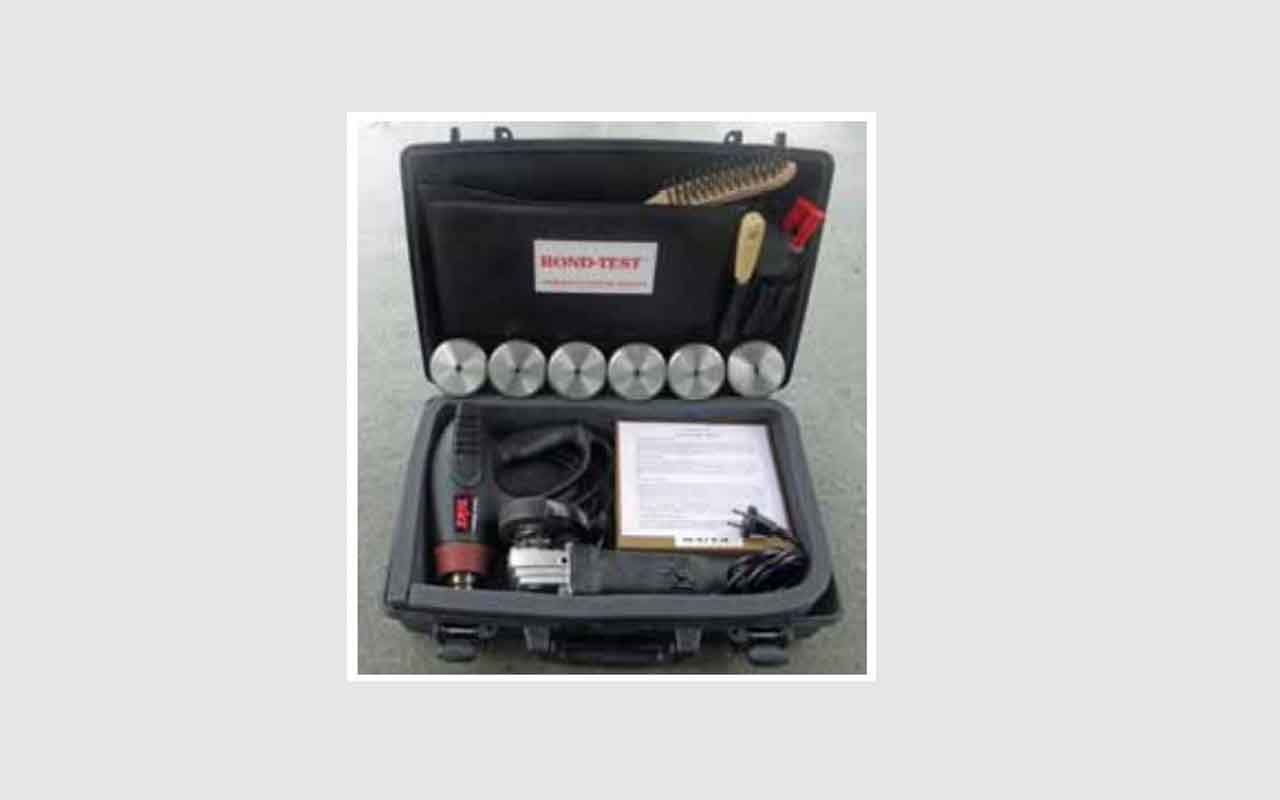

The BOND-TEST procedure

1. Surface planing

The surface is ground with a diamond studded planing tool to expose the aggregates and to obtain a plane surface. The center knob that remains is removed with a separate wheel grinder. The dry surface is steel brushed and any dust or powder is blown away. The suction plate is used to stabilize the planing tool. Note that this operation is done without using cooling water.

2. Bonding the disc

A clean disc is bonded to the prepared surface using a rapid-curing adhesive (GRA). The GRA adhesive has a tensile strength of 10 MPa when fully cured, which takes 2 to 5 minutes at normal temperatures. The progress of hardening is observed in the small cup in which the two-component GRA was mixed. In cold weather conditions, the concrete surface and the disc are heated with a heat gun to accelerate curing of the adhesive.

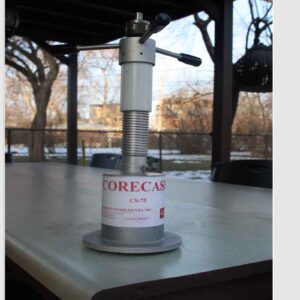

3. Partial coring

A partial core is cut perpendicular to the surface using cooling water; the bonded disc serves as a drill guide (the inner diameter of the coring bit is slightly larger than the disc diameter) . The partial core is cut with the CORECASE. For tests to measure bond strength, the core is cut to a depth of 25 mm into the substrate or one-half of the core diameter, whichever is greater; for tensile strength of the substrate, cut to a depth of 25 mm.

4. Pull-off

The disc is loaded in direct tension at a controlled rate using a calibrated hydraulic pull machine. The machine, which is the same as used for pullout tests, bears against a circular counter pressure ring positioned centrally on the planed surface. The peak force in kN is recorded and used to obtain the pull-off strength by dividing by the cross-sectional area of the partial core. The type of failure, (a), (b) or (c), as shown on the previous page, is recorded.

The procedure and special equipment used for the BOND-TEST ensure that the disc is loaded in direct tension without bending. Bending may lower results by 20 to 50 %. The discs have sufficient stiffness to avoid distortion during testing. By bonding a clean disc on a planed, dry surface with the GRA adhesive, failure should not occur at the disc/overlay interface. Failure at the disc/overlay interface is an inconclusive test and must be repeated if the bond strength is to be evaluated.

Understanding the Bond Pull Off Test

The Bond Pull Off Test, often referred to as the Pull Test, is a widely used method for evaluating the adhesion strength between two materials. This test assesses the force required to pull a material apart, thereby quantifying the adhesive strength between the substrate and the bonded material. The results of this test are crucial in numerous industries, including construction, automotive, aerospace, and manufacturing.

Principles of the Bond Pull Off Test

At its core, the Bond Pull Off Test operates on the principle of applying an increasing force perpendicular to the bonded surface until the bond fails. The force is applied gradually, allowing for precise measurement of the point at which the bond separates. This quantifiable data provides valuable insights into the adhesive properties of the materials being tested.

Applications of the Bond Pull Off Test

The versatility of the Bond Pull Off Test renders it invaluable across a spectrum of applications:

1. Construction Industry:

Assessing the adhesion strength of concrete and mortar in construction projects.

Evaluating the bonding quality of tiles, coatings, and sealants.

2. Automotive Sector:

Testing the adhesive strength of car body panels and components.

Ensuring the durability of paints and coatings on vehicles.

3. Aerospace Engineering:

Verifying the adhesive properties of materials used in aircraft manufacturing.

Assessing the strength of composite materials crucial for aerospace applications.

4. Manufacturing Processes:

Quality control of bonded joints in manufacturing various products.

Assessing the adhesion strength of labels, decals, and other surface-mounted items.

Significance of the Bond Pull-Off Test

The Bond Pull Off Test holds immense significance due to several factors:

1. Safety and Reliability:

Ensures that structures and products are safe for use by verifying the integrity of bonds.

2. Quality Assurance:

Helps manufacturers maintain quality standards by evaluating the adhesion strength of products.

3. Prevents Failures:

Identifies weak bonds, preventing catastrophic failures in critical applications.

4. Research and Development:

Aids researchers in developing new adhesives and materials with superior bonding properties.

Bond Pull Off Test Procedure

Performing a Bond Pull Off Test involves meticulous steps to ensure accurate results:

1. Surface Preparation:

Clean the surfaces thoroughly to remove contaminants that might affect the bond.

2. Application of Load:

Gradually apply force perpendicular to the bonded surface until the bond fails.

3. Recording Data:

Measure the force applied and the area over which it was distributed.

4. Analysis:

Analyze the results to understand the adhesion strength and failure mode.

Advantages of the Bond Pull Off Test

The Bond Pull Off Test offers several advantages, making it a preferred choice for assessing material adhesion:

1. Precision:

Provides precise data on adhesion strength, aiding in accurate analysis.

2. Non-Destructive:

Can be performed without causing significant damage to the tested materials.

3. Versatility:

Applicable to a wide range of materials, including metals, composites, and polymers.

4. Quantifiable Results:

Generates quantifiable results, allowing for easy comparison and analysis.

FAQs about Bond Pull Off Test

Q1: What is the Bond Pull Off Test?

The Bond Pull Off Test, also known as the Pull Test, is a method used to assess the adhesion strength between two materials by applying force perpendicular to the bonded surface until the bond fails.

Q2: Which industries commonly use the Bond Pull Off Test?

The Bond Pull Off Test is extensively used in the construction, automotive, aerospace, and manufacturing industries to evaluate the adhesive properties of various materials.

Q3: How is the Bond Pull Off Test performed?

The test involves preparing the surfaces, applying force gradually until the bond fails, recording the data, and analyzing the results to understand adhesion strength and failure mode.

Q4: What are the advantages of the Bond Pull Off Test?

The test offers precision, non-destructiveness, versatility, and provides quantifiable results, making it a preferred choice for material adhesion assessment.

Q5: Can the Bond Pull Off Test be performed on different types of materials?

Yes, the Bond Pull Off Test is applicable to a wide range of materials, including metals, composites, polymers, and coatings.

Q6: Is the Bond Pull Off Test a destructive testing method?

While the test does cause the bond to fail, it can be performed in a manner that minimizes damage to the tested materials, making it relatively non-destructive.

Q7: How is the data obtained from the Bond Pull Off Test analyzed?

The data, including the force applied and the area over which it was distributed, is analyzed to determine the adhesion strength and understand the failure mode, providing valuable insights for further evaluation.

Q8: Can the Bond Pull Off Test be used for quality control in manufacturing?

Yes, the Bond Pull Off Test is commonly used for quality control in manufacturing processes, ensuring the integrity of bonded joints and surface-mounted items.

Q9: What role does the Bond Pull Off Test play in aerospace engineering?

In aerospace engineering, the Bond Pull Off Test is vital for verifying the adhesive properties of materials used in aircraft manufacturing, ensuring the safety and reliability of aerospace components.

Q10: Is surface preparation essential for accurate Bond Pull Off Test results?

Yes, proper surface preparation, including thorough cleaning to remove contaminants, is essential to obtain accurate and reliable results from the Bond Pull Off Test.

Conclusion

In the ever-evolving landscape of materials science and engineering, the Bond Pull Off Test stands as a beacon of reliability, offering invaluable insights into the adhesion strength of materials. From ensuring the safety of skyscrapers to enhancing the efficiency of aircraft, this test plays a pivotal role in diverse industries. Its precision, versatility, and ability to provide quantifiable data make it an indispensable tool for researchers, manufacturers, and engineers alike. As technology advances and materials become more complex, the Bond Pull Off Test continues to be a cornerstone in the quest for stronger, safer, and more durable materials, shaping the future of countless industries.

Reviews

There are no reviews yet.